- Home Page

- Company Profile

-

Our Products

- Plastic Mixer Machine

- Plastic Scrap Grinder Machine

- Plastic Scrap Grinder Machine

- Plastic Scrap Grinder Machine

- Plastic Scrap Grinder Machine

- Plastic Scrap Grinder Machine

- Plastic Scrap Grinder Machine

- Plastic Scrap Grinder Machine

- Plastic Scrap Grinder Machine

- PET Bottle Scrap Grinding Machine

- HDPE Scrap Grinder Machine

- Semi Automatic PET Bottle Grinding Machine

- Plastic Waste Grinding Machine

- Pet Bottles Scrap Grinder Machine

- Plastic Grinding Machines

- HDPE Waste Grinding Machine

- Automatic HDPE Bottle Grinding Machine

- Dana Machine

- Vented Granule Machine

- Hydro Machine

- Agro Mixer Machine

- Plastic Recycling Machine

- Plastic Recycling Machinery

- PET Bottle Recycling Machine

- PET Waste Plastic Recycling Machine

- Automatic Pet Bottle Recycling Machine

- Two Stage Plastic Recycling Machine

- Plastic Recycling Machine

- Automatic Plastic Recycling Machine

- Plastic Bottles Recycle Machine

- Waste Recycling Machine

- Plastic Granules Making Machine

- Plastic Dana Making Machine

- Recycling Plant and Machinery

- Plastic Making Machine

- Plastic Scrap Washing Machine

- Plastic Color Mixer

- Plastic Shredder Machine

- Shredding Machine

- Plastic Dana Making Machine

- Waste Shredder Machine

- PET Bottle Shredder

- Plastic Extruder Machine

- Hydro Extractor

- High Speed Mixer

- PET Bottle Washing Plant

- Twin Screw Barrel

- Hydraulic Screen Changer

- Plastic Dryer Machine

- Dana Cutter Machine

- Plastics Mixers

- Bottle Washing Machine

- Plastic Processing Machine

- Lathe Machine

- Paint Mixing Machine

- HM Blown Film Plant

- Blade Grinding Machine

- Bottle Crusher Machine

- Pet Bottle Grinding Machine

- Powder Color Mixer

- Sutli Making Machine

- Plastic Blow Molding Machine

- Rubber Extruder Machine

- Contact Us

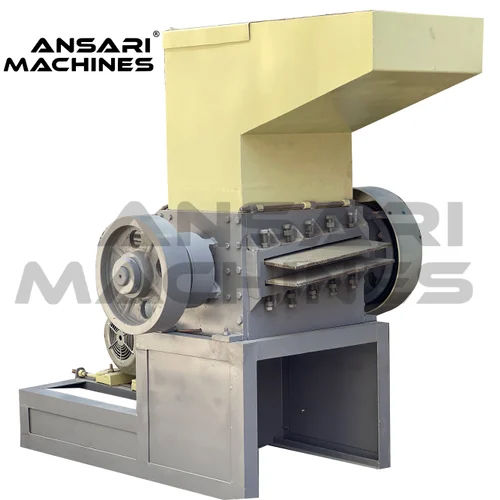

Double Shaft Metal Shredding Machine

750000 INR/Unit

Product Details:

- Material Alloy Steel Blade, Heavy-duty Steel Structure

- Voltage 380V / 415V

- Motor Power 22 kW x 2 (Total 44 kW)

- Application Metal Scrap Recycling, Automotive Parts, E-Waste, Aluminum, Steel, Tin Cans

- Automatic Grade Automatic

- Sheet Capacity Customizable per Requirement

- Control System PLC Control

- Click to View more

X

Double Shaft Metal Shredding Machine Price And Quantity

- 750000 INR/Unit

- 1 Unit

Double Shaft Metal Shredding Machine Product Specifications

- 3500mm x 2200mm x 2100mm (L x W x H)

- Shredding

- 5-20 mm (input material admissible)

- Less than 75 dB

- 50 Hz / 60 Hz

- Industrial Blue & Yellow

- Approx 4500 Kg

- 2-6 Tons per Hour

- PLC Control

- Customizable per Requirement

- Automatic

- Metal Scrap Recycling, Automotive Parts, E-Waste, Aluminum, Steel, Tin Cans

- 22 kW x 2 (Total 44 kW)

- 380V / 415V

- Alloy Steel Blade, Heavy-duty Steel Structure

Double Shaft Metal Shredding Machine Trade Information

- 10-15 Days

- All India

Product Description

Hot deal alert: Presenting the Double Shaft Metal Shredding Machine, praised for its unassailable performance and favorable reviews. Featuring robust twin shafts and potent high-strength alloy steel blades (imported/custom option), it shreds effortlessly at 2-6 tons/hour. The hydraulic pusher/manual feeding with overload protection ensures flawless operation, while the heavy-duty gearbox guarantees unmatched reduction. Centralized automatic lubrication, PLC control, and emergency stop provide exceptional reliability. Now available at clearance prices. Ideal for manufacturers and suppliers seeking flawless metal scrap shredding across automotive, e-waste, and industrial sectors in India.

Outstanding Features & Application Versatility

The Double Shaft Metal Shredding Machine comes equipped with advanced automatic lubrication and PLC-controlled operation, ensuring seamless shredding. It is exceptionally suited for processing metal scraps, automotive parts, steel sheets, tin cans, and e-waste. Its potent hydraulic pusher adapts effectively to diverse input surfaces, whether industrial steel structures or aluminum sheets. Reliability and customization make it perfect for factories, recycling plants, and workshops demanding precision and durability in handling heavy-duty materials.

FOB Port, Rapid Supply, & Sample Provision

Quick dispatch guaranteed from major ports in India, with efficient goods transport and professional handover to assure smooth delivery. The supply ability meets industrial-scale demands with prompt shipment schedules. Sampling is available upon request, enabling customers to verify the robust design and metal shredding efficiency firsthand before purchase. Reliable export logistics ensure timely transactions, making this machine a reliable investment for manufacturers and distributors seeking powerful recycling solutions.

Outstanding Features & Application Versatility

The Double Shaft Metal Shredding Machine comes equipped with advanced automatic lubrication and PLC-controlled operation, ensuring seamless shredding. It is exceptionally suited for processing metal scraps, automotive parts, steel sheets, tin cans, and e-waste. Its potent hydraulic pusher adapts effectively to diverse input surfaces, whether industrial steel structures or aluminum sheets. Reliability and customization make it perfect for factories, recycling plants, and workshops demanding precision and durability in handling heavy-duty materials.

FOB Port, Rapid Supply, & Sample Provision

Quick dispatch guaranteed from major ports in India, with efficient goods transport and professional handover to assure smooth delivery. The supply ability meets industrial-scale demands with prompt shipment schedules. Sampling is available upon request, enabling customers to verify the robust design and metal shredding efficiency firsthand before purchase. Reliable export logistics ensure timely transactions, making this machine a reliable investment for manufacturers and distributors seeking powerful recycling solutions.

FAQ's of Double Shaft Metal Shredding Machine:

Q: How does the Double Shaft Metal Shredding Machine ensure operator safety during operation?

A: The machine is equipped with overload and reverse rotation protection and features an emergency stop, centralizing all safety measures to prevent accidents and safeguard operators throughout continuous duty operations.Q: What types of materials can this shredding machine process effectively?

A: It is engineered to handle a wide range of input media, including automotive parts, metal scrap, steel and aluminum sheets, tin cans, and e-waste, making it highly versatile across recycling and manufacturing industries.Q: Where is the primary application area for this machine?

A: This shredding system is widely used in metal scrap recycling centers, automotive recycling units, electronic waste processing plants, and industrial factories for efficient and reliable material reduction.Q: What benefits does the twin shaft design offer compared to single shaft shredders?

A: The twin shaft design ensures unassailable shredding power, flawless material handling, and enhanced throughput capacity, enabling efficient reduction of large, heavy, and tough materials without compromising on speed or uniformity.Q: How is the control and automation managed in the machine?

A: Its advanced PLC control system automates operations and integrates with a centralized automatic lubrication system, delivering consistent functionality and minimizing downtime during continuous processes.Q: Can the machine's sheet capacity and discharge system be customized?

A: Yes, the sheet capacity is customizable as per specific user requirements, and clients may select between conveyor or ejector discharge systems, adapting the solution to distinct workflow needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email