- Home Page

- Company Profile

-

Our Products

- Plastic Mixer Machine

- Plastic Scrap Grinder Machine

- Plastic Scrap Grinder Machine

- Plastic Scrap Grinder Machine

- Plastic Scrap Grinder Machine

- Plastic Scrap Grinder Machine

- Plastic Scrap Grinder Machine

- Plastic Scrap Grinder Machine

- Plastic Scrap Grinder Machine

- PET Bottle Scrap Grinding Machine

- HDPE Scrap Grinder Machine

- Semi Automatic PET Bottle Grinding Machine

- Plastic Waste Grinding Machine

- Pet Bottles Scrap Grinder Machine

- Plastic Grinding Machines

- HDPE Waste Grinding Machine

- Automatic HDPE Bottle Grinding Machine

- Dana Machine

- Vented Granule Machine

- Hydro Machine

- Agro Mixer Machine

- Plastic Recycling Machine

- Plastic Recycling Machinery

- PET Bottle Recycling Machine

- PET Waste Plastic Recycling Machine

- Automatic Pet Bottle Recycling Machine

- Two Stage Plastic Recycling Machine

- Plastic Recycling Machine

- Automatic Plastic Recycling Machine

- Plastic Bottles Recycle Machine

- Waste Recycling Machine

- Plastic Granules Making Machine

- Plastic Dana Making Machine

- Recycling Plant and Machinery

- Plastic Making Machine

- Plastic Scrap Washing Machine

- Plastic Color Mixer

- Plastic Shredder Machine

- Shredding Machine

- Plastic Dana Making Machine

- Waste Shredder Machine

- PET Bottle Shredder

- Plastic Extruder Machine

- Hydro Extractor

- High Speed Mixer

- PET Bottle Washing Plant

- Twin Screw Barrel

- Hydraulic Screen Changer

- Plastic Dryer Machine

- Dana Cutter Machine

- Plastics Mixers

- Bottle Washing Machine

- Plastic Processing Machine

- Lathe Machine

- Paint Mixing Machine

- HM Blown Film Plant

- Blade Grinding Machine

- Bottle Crusher Machine

- Pet Bottle Grinding Machine

- Powder Color Mixer

- Sutli Making Machine

- Plastic Blow Molding Machine

- Rubber Extruder Machine

- Contact Us

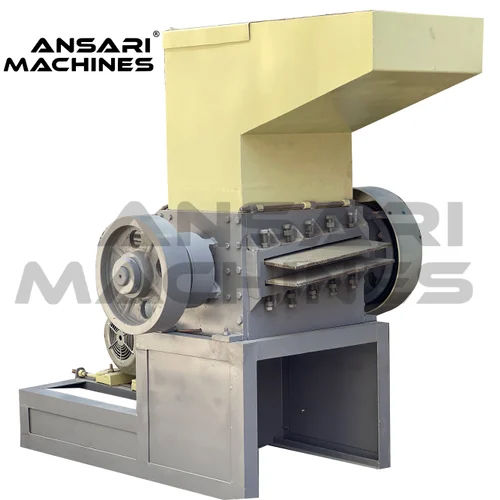

Metal Industrial Shredders

860000 INR/Unit

Product Details:

- Motor Power 40 HP

- Material Mild Steel

- Thickness Up to 20 mm

- Sheet Capacity Multiple Sheets

- Capacity 1000-3000 kg/hr

- Voltage 415 V

- Control System PLC Control

- Click to View more

X

Metal Industrial Shredders Price And Quantity

- 860000 INR/Unit

- 1 Unit

Metal Industrial Shredders Product Specifications

- Low

- Metal Scrap Shredding

- 50 Hz

- 2500 mm x 1200 mm x 1800 mm

- PLC Control

- Metal Shredding

- 3200 kg

- Blue & Black

- Automatic

- Mild Steel

- 40 HP

- 415 V

- Multiple Sheets

- 1000-3000 kg/hr

- Up to 20 mm

Metal Industrial Shredders Trade Information

- 20-30 Days

- All India

Product Description

Find the grand solution to metal scrap management with our Terrific Metal Industrial Shredders. Featuring a sublime Rotary Cutter System and Double Shaft configuration, these machines are engineered with alloy steel blades for optimized durability. Try Now to experience seamless conveyor feeding, automatic discharge, and PLC-controlled operations. The Markdown on safety is unmatched-emergency stops, interlock doors, and overload protections ensure secure usage. With adjustable shredding output from 30-100 mm and a powerful 40 HP electric drive, it suits heavy-duty applications, delivering low noise and efficient processing for industry leaders across India.

Versatile Industrial Metal Shredding: Usage & Operation

This shredder excels at continuous metal scrap processing in industrial and manufacturing environments. Its grand capacity allows multiple sheets up to 20 mm thickness, making it ideal for large-scale usage. Simply feed metal waste via the automatic conveyor and let the system work in a continuous mode for high output. The integrated control system with sublime PLC monitoring ensures direction of use is straightforward-just set your parameters, engage safety features, and process bulk metal efficiently.

Export Excellence & Domestic Reach

Our Metal Industrial Shredders capture a sizable share in both domestic and export markets, delivering superior value to clients. Based in India, we offer worldwide shipment through recognized FOB ports, reducing your expenditure while ensuring timely delivery. With a supply ability of 1000-3000 kg/hr, these shredders meet the grand expectations of global partners. Whether scaling domestic manufacturing or expanding to international regions, trust our product to boost metal scrap processing and enhance operational efficiency.

Versatile Industrial Metal Shredding: Usage & Operation

This shredder excels at continuous metal scrap processing in industrial and manufacturing environments. Its grand capacity allows multiple sheets up to 20 mm thickness, making it ideal for large-scale usage. Simply feed metal waste via the automatic conveyor and let the system work in a continuous mode for high output. The integrated control system with sublime PLC monitoring ensures direction of use is straightforward-just set your parameters, engage safety features, and process bulk metal efficiently.

Export Excellence & Domestic Reach

Our Metal Industrial Shredders capture a sizable share in both domestic and export markets, delivering superior value to clients. Based in India, we offer worldwide shipment through recognized FOB ports, reducing your expenditure while ensuring timely delivery. With a supply ability of 1000-3000 kg/hr, these shredders meet the grand expectations of global partners. Whether scaling domestic manufacturing or expanding to international regions, trust our product to boost metal scrap processing and enhance operational efficiency.

FAQ's of Metal Industrial Shredders:

Q: How does the double shaft rotary cutter system improve metal shredding efficiency?

A: The double shaft rotary cutter system enhances shredding by providing powerful and synchronized cutting action, enabling efficient processing of metal scraps into adjustable output sizes (30-100 mm) with consistent performance.Q: What safety features are included in the Metal Industrial Shredder?

A: Safety is prioritized with emergency stop buttons, interlock doors, automatic discharge, and overload/reverse protection mechanisms, all designed to ensure secure and safe usage during operation.Q: Where can the Metal Industrial Shredder be used?

A: These shredders are grand for industrial applications, scrap yards, metal processing units, and recycling centers, offering versatility for both domestic and export markets.Q: When is automatic discharge activated in the shredding process?

A: Automatic discharge is initiated once metal scraps reach the set output size, allowing processed materials to be expelled without manual intervention, streamlining workflow.Q: What is the main benefit of conveyor feeding in this shredder?

A: Conveyor feeding allows continuous loading of metal scraps, reducing manual effort and enhancing throughput, which in turn increases productivity and operational efficiency.Q: How can users adjust the shredding output size?

A: Users can easily set the output size within the range of 30-100 mm through the PLC control system, allowing customization according to specific requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email